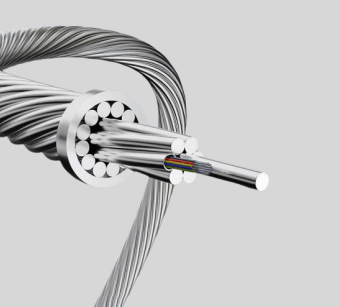

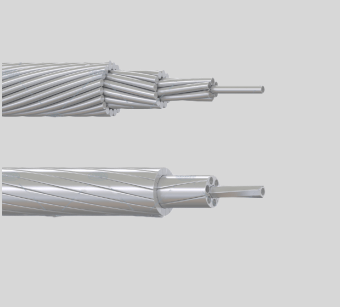

Alumium clad steel wire is more durable than other options in corrosive environments, resulting in lower maintenance and replacement costs.

Aluminum clad steel wire is lighter than steel strands of the same size, when used for overhead ground wires, larger span lengths, less sag, and heavier loads can be achieved, thereby reducing the tension on the tower or support structure and the tower, the frame stress is reduced accordingly.

| GB/T 17937 |

IEC 61232 |

DIAMETER (mm) |

TENSILE STRENGTH (MPa) |

STRESS AT 1% EXTENSION (MPa) |

| LB10 | 2.66<d≤3.00 | 1234 | 1153 | |

| LB14 | _ | 2.25<d≤3.50 | 1994 | 1663 |

| 3.00<d≤3.50 | 1550 | 1380 | ||

| 3.50<d≤4.75 | 1773 | 1429 | ||

| 4.75<d≤5.50 | 1500 | 1270 | ||

| LB20A | 20SA-A | 1.24<d≤3.25 | 1414 | 1272 |

| 3.25<d≤3.45 | 1310 | 1180 | ||

| 3.45s<d≤3.65 | 1493 | 1305 | ||

| 3.65<d≤3.95 | 1378 | 1165 | ||

| 3.95<d≤4.10 | 1210 | 1100 | ||

| 4.10<d≤4.40 | 1180 | 1070 | ||

| 4.40<d≤4.60 | 1140 | 1030 | ||

| 4.60<d≤4.75 | 1100 | 1000 | ||

| 4.75<d≤5.50 | 1070 | 1000 | ||

| LB20B | 20SA-B | 1.24<d≤5.50 | 1320 | 1100 |

| LB25 | _ | 2.50<d≤3.00 | 1557 | 1178 |

| LB23 | _ | 2.50<d≤5.00 | 1220 | 980 |

| LB27 | 27SA | 2.50<d≤5.00 | 1080 | 800 |

| LB30 | 30SA | 2.50<d≤5.00 | 880 | 650 |

| LB35 | _ | 2.50<d≤5.00 | 810 | 590 |

| LB40 | 40SA | 2.50<d≤5.00 | 680 | 500 |

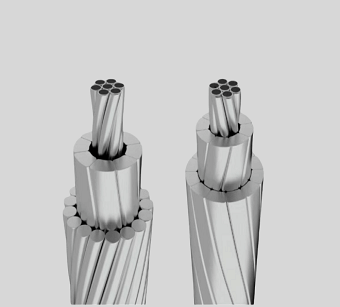

| STRUCTURE | 3AS | 7AS | 19AS |

| Cross-sectional Area |  |

|

|

| No./size of strands |

Cross section |

No. of wires | Diameter | Approx. weight | Rated strength | Max. DC resistance at 20℃ |

|

| Wire | Conductor | ||||||

| AWG | mm² | 3 | mm | mm | kg/km | kN | Ω/km |

| 3 No. 5 | 50.32 | 3 | 4.62 | 9.96 | 334.1 | 54.42 | 1.6990 |

| 3 No. 6 | 39.80 | 3 | 4.11 | 8.87 | 265.0 | 45.74 | 2.1420 |

| 3 No. 7 | 31.65 | 3 | 3.67 | 7.90 | 210.1 | 38.36 | 2.7010 |

| 3 No. 8 | 25.10 | 3 | 3.26 | 7.03 | 166.7 | 32.06 | 3.4060 |

| 3 No. 9 | 19.90 | 3 | 2.91 | 6.26 | 132.2 | 25.43 | 4.2940 |

| 3 No. 10 | 15.78 | 3 | 2.59 | 5.58 | 104.8 | 20.16 | 5.4150 |

| 7 No. 5 | 117.40 | 7 | 4.62 | 13.90 | 781.1 | 120.27 | 0.7426 |

| 7 No. 6 | 93.10 | 7 | 4.11 | 12.4 | 619.5 | 101.14 | 0.9198 |

| 7 No. 7 | 73.87 | 7 | 3.67 | 11.00 | 491.1 | 84.81 | 1.1600 |

| 7 No. 8 | 58.56 | 7 | 3.26 | 9.78 | 389.6 | 70.88 | 1.4630 |

| 7 No. 9 | 46.44 | 7 | 2.91 | 8.71 | 308.9 | 56.20 | 1.8440 |

| 7 No. 10 | 36.83 | 7 | 2.59 | 7.76 | 245.1 | 44.58 | 2.3250 |

| 7 No. 11 | 29.21 | 7 | 2.30 | 6.91 | 194.4 | 35.35 | 2.9320 |

| 7 No. 12 | 23.16 | 7 | 2.05 | 6.16 | 154.2 | 28.03 | 3.6970 |

| 19 No. 5 | 318.70 | 19 | 4.62 | 23.10 | 2129.0 | 326.39 | 0.2698 |

| 19 No. 6 | 252.70 | 19 | 4.11 | 20.60 | 20.60 | 1688.0 | 0.3402 |

| 19 No. 7 | 200.40 | 19 | 3.67 | 18.30 | 18.30 | 1339.0 | 0.4290 |

| 19 No. 8 | 158.90 | 19 | 3.26 | 16.30 | 16.30 | 1062.0 | 0.5409 |

| 19 No. 9 | 126.10 | 19 | 2.91 | 14.50 | 14.50 | 842.0 | 0.6821 |

| 19 No. 10 | 99.96 | 19 | 2.59 | 2.59 | 12.90 | 667.7 | 0.8601 |

| CHARACTERISTICS OF WIRES |

UNIT | 14(E)(U)HSA |

20(EH)SA |

27SA |

30SA |

40SA |

|

| A | B | ||||||

| Final modulus of elasticity | GPa | 174 | 162 | 155 | 140 | 132 | 109 |

| Coefficient of linear expansion |

K-1 | 11.9 x 10-06 | 13 x 10-06 | 12.6x 10-06 | 13.4x 10-06 | 13.8x 10-06 | 15.5 x 10-06 |

| Temperature coefficient ofresistance to constant mass (α) |

K-1 | 0.0036 | 0.0036 | 0.0036 | 0.0038 | 0.004 | |

| Density | Kg/dm3 | 7.29 | 6.59 | 6.53 | 5.91 | 5.61 | 4.64 |

| Resistivity max. | ηΩ.m | 123.15 | 84.8 | 63.86 | 57.47 | 43.1 | |

| Conductivity | % IACS |

14 | 20.3 | 27 | 30 | 40 | |

| Auminum minimum thickness |

% radio | 4.6 | 8/10 | 14 | 15 | 25 | |

| Aluminum proportion in cross section |

% | 10 | 25 | 37 | 43 | 62 | |

| Alloy | Material: Chrtome-plated Brass |

| Temper | Material: Chrtome-plated Brass |

| Thickness(mm) | Material: Chrtome-plated Brass |

| Width(mm) | Material: Chrtome-plated Brass |

| Length(mm) | Material: Chrtome-plated Brass |

| Application | Material: Chrtome-plated Brass |

Medium and high fatigue grades TD and VD are characterized by high steel cleanliness, specific chemical.mechanical and technological parameters and a well defined surface condition in relation to the allowable depth of surface defects and decarburization.

The static grade FD is characterized by its chemical, mechanical and technological characteristics as well as by a specified surface condition concerning surface defects and decarburization.

If you have any question about the company's legal policy, copyright, trademark, other legal topics, or general product and service related queries, please fill in the form. We will reply you as soon as possible!